Using our new Thermal Imaging camera we were able to see some significant problems in the insulation of our exterior walls. The cellulose insulation was specified to be installed to a so-called “dense-pack” density, which compresses the material enough that it will not settle. But alas our contractor did not do it as specified, and in the 3 years since it was installed there has been significant settling in the walls. We had just a vague sense that the house was not retaining heat as well as it originally did, until we used a Thermal Imaging camera to make the problems visible.

Once we could see where the problems were, Jay had to crawl through the attic to the tops of the exterior walls and stuff more insulation down into them by hand. It was a very Dirty Job and not practical to photograph, but now that it’s done we can clearly see the difference in the infrared images. We can also tell the difference inside, where the bedrooms stay one or two degrees warmer than they did before with similar outside temperatures.

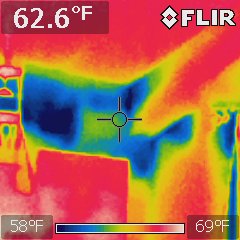

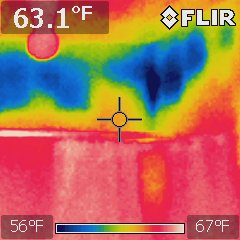

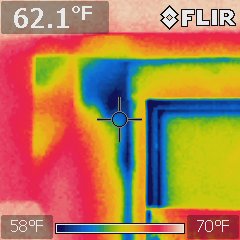

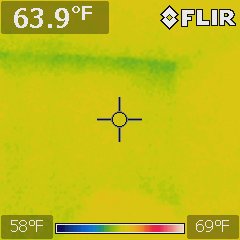

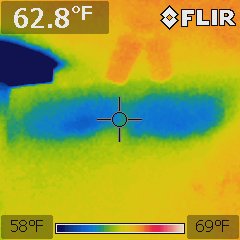

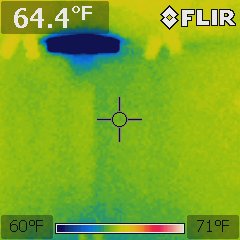

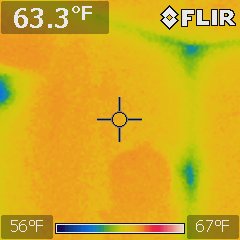

In the series of photos below, each set of three pictures shows a shot of an exterior wall area taken with a regular digital camera, followed by thermal images taken before and after fixing the insulation. The pictures are not framed exactly the same in each set since they were taken at different times, but in each case they show the same general area. The indicated absolute temperatures of the surfaces are not significant because we didn’t calibrate the camera for absolute temperatures, and the colors are not very significant either; what matters is the huge reduction in the temperature variation before and after. It’s plain to see where the walls had no insulation at all, and that filling them up made a big difference.

|

Visible Image |

Thermal Image – Before |

Thermal Image – After |

|

|

|

|

|

|

|

|

|

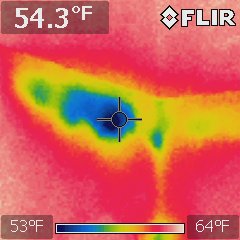

In the very last photo above, you can see some cooler areas shown in blue along the corners of the walls. It is normal for surfaces to be slightly cooler in the corners because there is less interior air circulation there, but the significantly colder spot at the lower right of the photo cannot be explained simply by reduced air circulation. It is most likely a small gap remaining in the insulation, or perhaps a thermal bridge where the inner wall framing is tied to the exterior walls in a few places. It’s not a major concern because, although it is a couple of degrees cooler there, the area is so small that its heat loss is not significant.

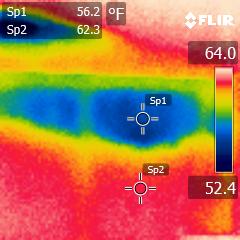

Since the original insulation had 3 years to settle and the newly added insulation is packed in pretty tightly, there is a good chance that no further settling will occur. But since we decided to invest in the thermal camera we can re-check it every year to make sure no new problems arise. So far we’ve only done the walls in the main house, and the exterior walls in the cottage section also show some significant insulation settling that we’ll need to fix before next winter: