Custom Threaded Adapters

The Adapt~O~Matic creates customized 3D-printable adapters for things like lenses and filters, or pretty much anything with metric or Unified threads. It creates well-formed thread profiles with smooth lead-in and lead-out, but doesn’t do NPT or other tapered thread profiles (yet). You can also create threaded lens caps, and adapters with smooth non-threaded ends if you want.

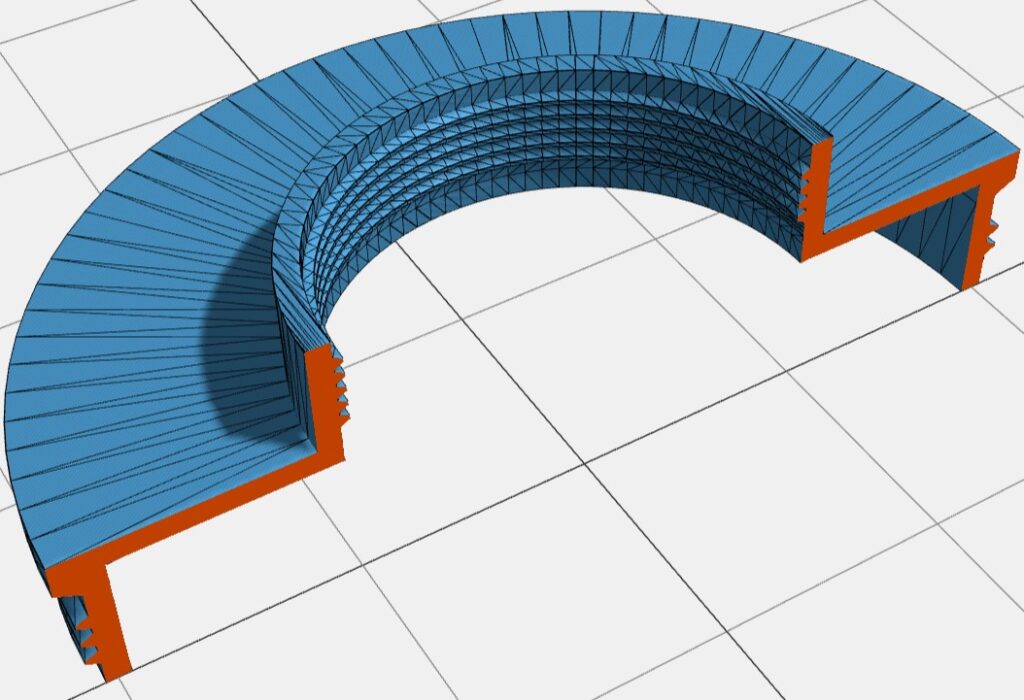

Above you should see an interactive 3D display showing the generated adapter, with an adjacent parameters panel showing the parameters you can customize. If you don’t see the display, try clearing your browser’s cache for this website and reloading the page. If that doesn’t work, it’s possible that your browser is not compatible so a different browser may work better. You can click the fullscreen button on the toolbar at the upper right of the 3D model viewer, to hide these instructions and maximize the model viewer and parameters. The buttons on the left of the toolbar will let you see cross-section and wireframe views of the model:

Once your adapter is configured as desired, press the Download button on the toolbar and your browser should download an STL file that can be loaded into any slicer program for 3D printing.

Adapter Parameters

There are quite a few parameters that can be adjusted to fine-tune the generated 3D geometry. Most of these are explained in the text that accompanies them, and here are some additional notes.

Measurement Units

Parameters that expect a length will accept various formats as illustrated in these examples. Spaces are ignored, and simple fractions are supported but not forms like “1-1/2 in”, so use decimal numbers for those. Case is ignored in all forms so M55 is the same as m55.

| What You Enter | What It Means |

| 55 or 55mm or M55 | 55 millimeters |

| 1.3in | 1.3 inches |

| 1/4in | 0.25 inches |

| 12TPI | 1/12 inches |

| 5T | 5 complete threads, applies to Thread Length parameter only |

For thread sizes, specify the nominal diameter and thread pitch separated with an x. Spaces are optional, and shown here for clarity. There are also aliases for some common thread sizes as shown in this table.

| What You Enter | What It Means |

| M42 x 1 | 42mm diameter, 1.0mm pitch |

| 3/4in x 10TPI | 0.75 inch diameter, 1/10 inch pitch |

| M26 x 36tpi | 26mm diameter, 1/36 inch (0.706mm) pitch (mixed units are fine) |

| 45 or 45mm or M45 | 45mm diameter, no threads |

| C-Mount or cmount | 1in x 32TPI |

| T-Mount or tmount | M42 x 0.75 |

| RMS | 0.8in x 36TPI as used on RMS microscope objectives |

| Mitutoyo or mitty | M26 x 36TPI as used on Mitutoyo microscope objectives |

Flanges

You can add protruding flanges for male threads, to provide a positive stop. The Flange Length and Flange Protrusion parameters control the size of the flanges, and it may take some experimentation to find the best settings for your application. Examine the 3D geometry closely, because with poorly-chosen settings it’s possible to create flanges that will not print well.

The Flange Angle setting controls the angle of the underside of a protruding flange, with zero meaning horizontal. It’s hard to print horizontal overhangs without support so the default is 30 degrees, which most printers can handle unsupported.

Circle Segments

Circles are approximated using a series of line segments, and this parameter controls how many segments make up a complete circle. The 3D preview uses a low segment count for faster display as you change parameters, and the Circle Segments parameter takes effect only when you open the Download Model dialog. You can increase the setting to get smoother curves, but it’s often not necessary because the thread allowance (see below) provides space between male and female threads that will tolerate slightly imperfect geometry.

Threaded Bushings

A compact form of step-down adapter will be generated under the following conditions:

- Nominal Length is blank

- Top thread is male

- Bottom thread is female and substantially smaller than the top

Here “substantially smaller” means that the solid wall between the outer and inner threads would be at least 0.5mm thick, which typically means that the nominal bottom thread size must be a few mm smaller than the top. Otherwise a less compact form of adapter will be generated.

If you want to create a bushing with a completely flat surface on top and female threads running the entire length, just leave the bottom Wall Thickness and Thread Length blank:

Threaded Caps

You can make a threaded cap by setting the bottom thread to Size=0 and Male=false (female). The top thread can be set to either male or female depending on the style of cap you want. Enable Knurling on the top thread for a better grip. A pair of caps like this also makes a nice threaded container.

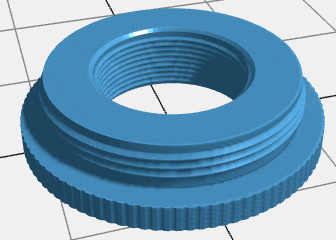

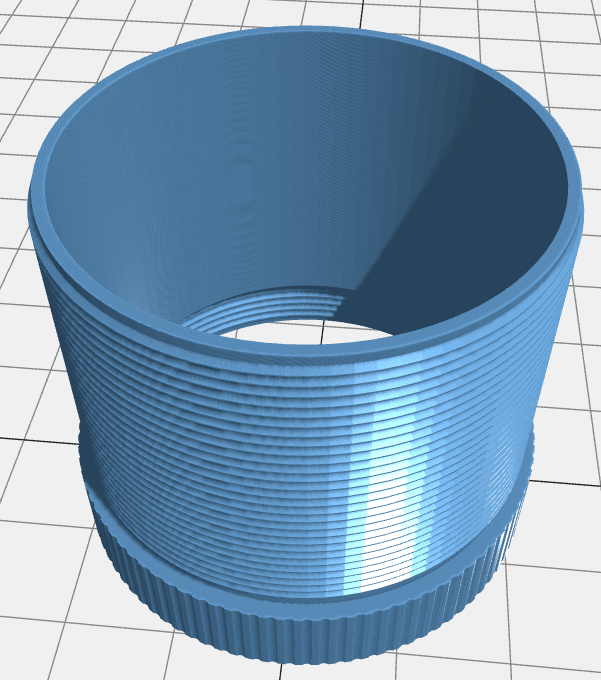

Adjustable Extension Tube

It’s easy to make an extension tube of any length you want, but what if you don’t know what length you want? Make an adjustable one! This is made as three separate components. First, set the same thread size for top and bottom, and set top thread to male and bottom to female. Set the top Thread Length relatively long such as 30mm, as the min/max range of the adjustable tube will be roughly 1.2X to 1.8X this length. Set the bottom Thread Length to about 5T, enable Knurling, and you’ll get a shape like the first image below. Download the male half for printing.

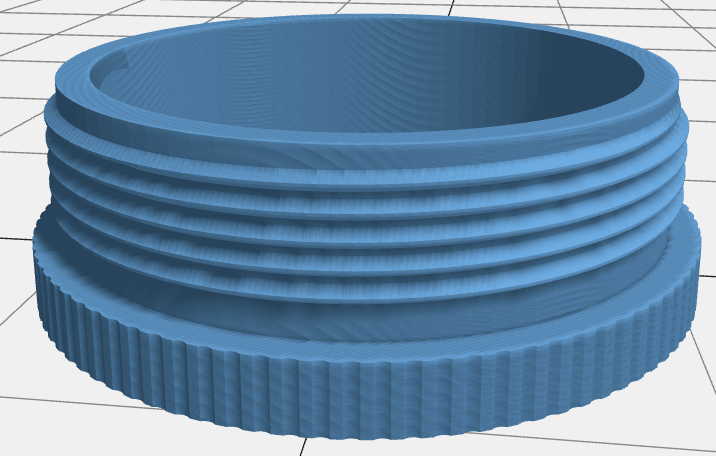

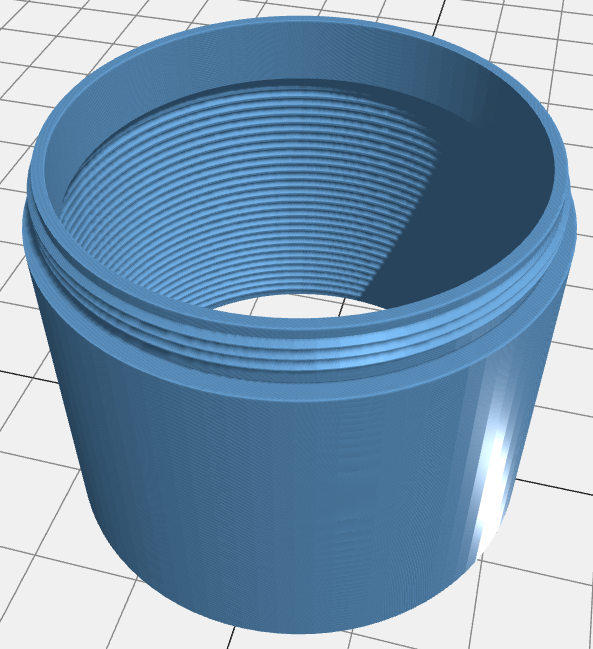

Next set the top Thread Length to about 3T and the bottom to female with a Thread Length about the same large value (e.g. 30mm) that you used above. Disable Knurling if you want a smooth outside like the second image below. Download the female half for printing.

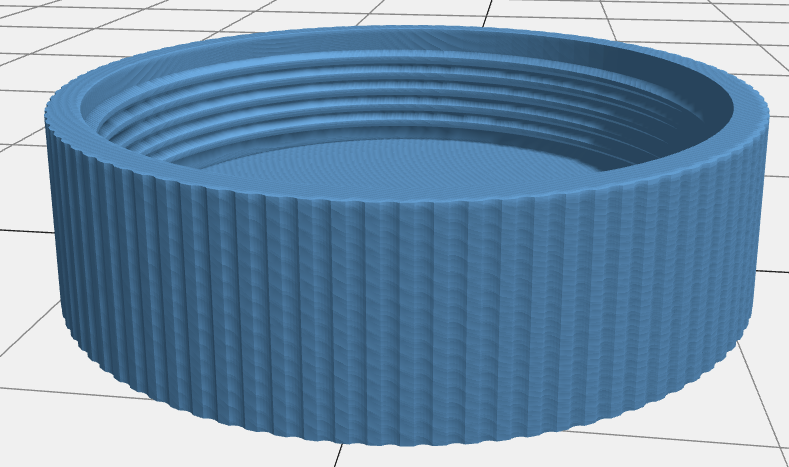

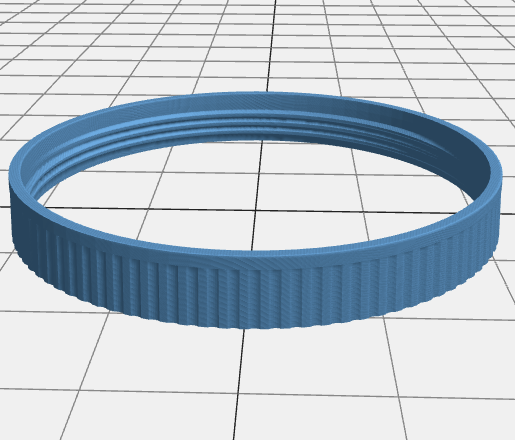

Finally, change the top thread to female with a length of zero, reduce the bottom thread length to about 2.5T, and you’ll get a “nut” as shown in the third photo. Download the nut for printing.

Once you’ve printed all three parts, thread the nut onto the male half and then thread on the female half to whatever overall length you want, and secure it with the nut.

3D Printing Tips

Many people are surprised that 3D printers can make usable fine-pitch threads like those on lens filters. The main factors affecting thread quality are layer height and printing speed, and if you adjust these carefully then a relatively ordinary 3D printer can do a pretty good job.

Too Tight or Too Loose?

The ‘Allowance’ parameters specify how much gap to create between male and female threads, because if they are precisely the same size then the fit will be very tight. The default setting works well enough for most conditions, but you can adjust the allowance to fine-tune the fit. A positive allowance makes male threads smaller, and female threads bigger. If your threads are too tight, increase the allowance in small increments. Conversely if your threads are too loose, decrease the allowance. You can even specify a negative allowance to account for material shrinkage, where the printed threads end up physically smaller than the nominal dimension.

Layer Height

The layer height is determined by your slicing software, and as a rule of thumb should be set to 10% to 15% of the thread pitch. For example most lens filters have a pitch of 0.75mm and a layer height of about 0.1mm works well. Smaller layers give better results but take longer to print. You can also use ‘adaptive layer height’ if your slicer supports it, to give a fine layer height where there are threads and a larger layer height in smooth sections for faster printing.

Printing Speed

If threads are coming out rough or malformed, try slowing down the print speed. You don’t have to go insanely slow but reducing to about 50% of typical print speed can improve thread quality. Most slicers have the ability to adjust print settings within user-specified regions so you can slow down the print speed only in the threaded regions if desired, but it’s usually not worth the trouble if you’re printing something relatively small. Adaptive layer height, as noted above, can have a much larger effect with much less effort.

Support

Most modern 3D printers can handle a slope that is 30 degrees from horizontal (60 degrees from vertical), which is the slope of the ISO / Universal thread profile, without any additional support – at least for short protrusions like threads. Large horizontal or nearly-horizontal areas will need support for printing, and modern slicer software does a good job of generating support that’s reasonably easy to remove. You may be able to avoid needing support by specifying an adapter length that keeps the walls closer to vertical. The Flange Angle setting affects protruding flanges, and its default of 30 degrees gives the underside of flanges a slope that should print acceptably without support. However it may slightly alter the effective flange-to-flange adapter length, so if necessary you can set it to zero and enable support in your slicer.

Filament

Most common filaments work adequately to print threaded adapters for light-duty use. PETG is a good choice for its superior abrasion-resistance compared to PLA. For optical applications such as extension tubes, you can try a matte black filament but you can get better light absorption with flocking or super-black paint inside.

Questions? Comments? Bugs? Requests?

Feel free to contact us if you like. Of course we won’t satisfy every request, but we promise to listen. If you want to share the exact settings you’re using, use the copy button at the bottom of the parameters panel to copy your parameters to your clipboard, then paste them into an email. Or if you prefer, you can use the save button to save them to a file that you can attach.